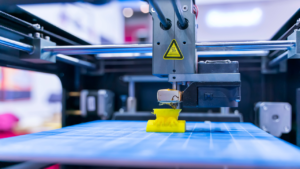

3D Printing Arizona uses computers to create objects by adding layer after layer of material until the final object is complete. This process starts with a virtual design made using computer-aided design (CAD) software.

This digital file is then “sliced,” which prepares it for the 3D printer to read. The sliced model is then uploaded to the printer.

Creating a prototype is usually the first step in designing a new product. It’s important to ensure that the prototype is accurate and will perform well in the real world. The best way to do that is with rapid prototyping. Rapid prototyping allows engineers to create a realistic proof of concept model and advance it to a high-fidelity prototype that looks and works like the final product. It also enables engineers to perform extensive functional testing and guide the product through a series of validation builds toward mass production.

Rapid prototyping helps companies develop innovative products at a much faster rate than traditional manufacturing methods. This is critical in today’s fast-moving consumer market, where many products are withdrawn from the marketplace after only a short period of time due to poor performance or quality issues.

With rapid prototyping, engineers can test designs and get feedback from stakeholders quickly and easily. They can also make changes to the design easily and without having to invest a lot of time or money. For example, if the prototype reveals that the product might be too difficult to handle for people with smaller or larger hands, they can adjust the design before it goes into production.

In addition, rapid prototyping allows companies to improve the quality of a new product early in the development process by identifying problems that would be difficult to detect with CAD models or drawings. This can save valuable time and resources in the long run by preventing expensive and complicated redesigns.

There are several different types of 3D printing processes available for rapid prototyping. The most popular is stereolithography (SLA). This method uses a UV laser to cure layers of photosensitive liquid resin to build the prototype. It is ideal for low-end functional prototypes, patterns and moulds, and production tools. Other options include selective laser melting (SLM), laminated object manufacturing (LOM), digital light processing (3D) and binder jetting.

The level of fidelity of a prototype depends on the specific project needs and the desired design iteration. A higher fidelity prototype typically has more precise geometry, tolerance and material properties, but can take longer to print and is usually more expensive.

Customization

3D Printing allows for customized products to be produced based on customer specifications. This customization has many benefits, including a higher level of product quality and increased customer satisfaction. Moreover, it can help companies reduce inventory and production costs. 3D printing technology also allows for the manufacture of parts without the need for tooling. Tooling requires a significant amount of manufacturing time and space, which can be expensive for small companies. In addition, changing a tooling process can take weeks or months.

With additive manufacturing, however, it is possible to create a product that meets specific customer requirements with little or no downtime. It is also possible to use a single part to produce multiple variants of a product. This can save a company significant production and maintenance costs. Furthermore, 3D printed products can be made to order and are often ready for use within days of being ordered.

This flexibility makes it easier to adapt to customer needs and market demands. This can be particularly beneficial for businesses with large numbers of different customers. It can also allow for more effective marketing campaigns.

Additionally, 3D Printing enables the creation of bespoke geometric parts that are impossible or extremely difficult to make using traditional methods. The layer-by-layer approach of 3D printers allows for the creation of complex geometries and intricate designs, which is a boon for industries like aerospace and medical care. For example, 3D-printed prosthetics are designed based on each individual patient’s anatomy, which ensures better fit and function and improves patient outcomes. Similarly, surgeons can utilize 3D-printed anatomical models based on CAT scan data to enhance their planning and learning processes.

In the construction industry, 3D Printing can be used to construct buildings. The technology is able to deliver modular building components, and can be assembled on-site in a fast and efficient manner. This can be particularly useful in the case of standardized housing initiatives, rapid response construction after disasters, and more.

The potential applications for 3D Printing are endless. With this technology becoming more affordable and more adaptable, it is poised to become a key tool in digital transformation strategies for small business. Learn more about what it can do for your business by requesting a demo today.

Efficiency

3D Printing is a great way to increase efficiency and reduce costs. It allows products to be produced faster and without the need for costly tooling. It also allows for the development of multiple SKUs in parallel. This can help shorten the time to market for new products and can improve productivity in existing production lines. In addition, it can help to eliminate the need for multiple rounds of re-designs before scale up and mass production can take place.

In addition, 3D Printing offers the ability to produce a wide range of materials that can be used in a variety of applications. This flexibility makes it possible to print a wide range of parts that can be used in various industries such as automotive, aerospace, and medical. Moreover, it can be used to create complex structures and components that are not feasible with conventional manufacturing processes. This includes structures with intricate details and customized shapes that can be used to improve the performance, sustainability, and cost of a product.

3D printed parts also have lower material costs than traditional manufactured parts. This is because there is no need to cut and shape the metal like in CNC machining or injection molding, which reduces the amount of material used to make the part. Moreover, the printing process is more environmentally friendly than other manufacturing methods as it produces a lot less waste material.

The only real waste generated by the 3D printing process is the support material that has to be removed after the build process. However, this is not a big problem, as there are several ways to minimize the amount of support material needed. For example, reorienting the part and building the structure at a self-supporting angle can significantly reduce the amount of support material required. Additionally, building the part on a flat surface can also decrease the amount of support material needed.

Another way to reduce the use of support material is by using a layer height that is appropriate for your application. Thicker layers may produce a better aesthetic, but they also require more material and can increase the overall price of the part.

Sustainability

With the increased awareness of climate change and its impacts, a growing number of organizations are prioritizing sustainable, environmentally conscious business practices. 3D Printing can play an important role in this effort by reducing both the energy consumed and carbon emissions associated with traditional manufacturing processes.

One of the most significant benefits of using 3D printers is that it eliminates the need for waste materials and scraps. Traditional manufacturing processes, such as injection molding and CNC milling, require a significant amount of material to produce one part, oftentimes creating considerable amounts of waste in the process. In addition, these waste materials must be disposed of, resulting in additional costs and environmental impact. 3D Printing, on the other hand, can create parts directly from digital files without the need for excess material or scraps, eliminating both of these expenses.

Additionally, many of the materials used in 3D Printing are derived from renewable resources such as plastics and melted thermoplastics. This reduces the use of non-renewable materials, which in turn contribute to resource depletion and global warming. Furthermore, 3D printers can be powered by renewable sources of energy, further reducing the environmental impact of these technologies.

The nature of 3D Printing also allows for the production of items on-demand, removing the need for large inventories and storage costs. This on-demand production also decreases the time it takes to deliver products to customers, allowing for more rapid responses to customer needs and improving overall customer satisfaction.

In addition to reducing waste, 3D Printing can make a more sustainable choice of materials by optimizing designs and minimizing material usage. For example, Fused Deposition Modelling (FDM) technology uses thermoplastics, such as polylactic acid, that are sourced from renewable resources. Moreover, 3D Printing can incorporate lattice structures into designs to maintain structural integrity while requiring less material, lowering the overall environmental footprint of the finished product.

Lastly, the localization of production with 3D Printing allows for lower transportation costs and emissions compared to traditional manufacturing methods. Most of the energy consumption in manufacturing is associated with transporting supplies and parts to various locations for processing and distribution, which can lead to significant amounts of greenhouse gases. By printing parts and prototypes close to home, businesses can substantially cut these energy costs and noxious emissions.